Why Export Banana Fiber Textiles from India NOW?

Going Green Never Looked So Good!

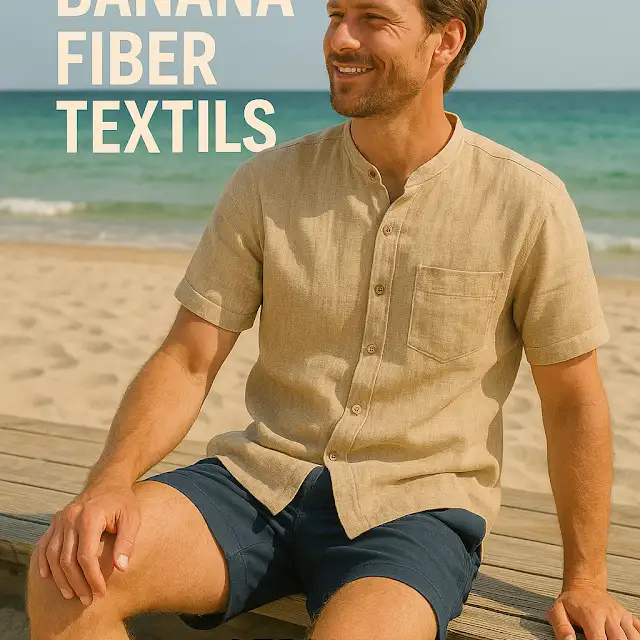

In a world fighting fast fashion’s footprint, Banana Fiber Textiles are emerging as the next big thing in sustainable fashion!

With growing global demand for biodegradable, ethical, and eco-luxury alternatives, India’s banana-rich south—Tamil Nadu & Kerala—is turning waste into wonder. India isn’t just meeting the trend; it’s leading it!

1. Introduction: Why You Should Start Exporting Banana Fiber Textiles from India Today

Sustainable is Sensible — The fashion industry is undergoing a seismic shift. As consumers and brands turn away from synthetic fibers, there's an urgent need for materials that are eco-friendly, durable, and ethical.

Banana fiber fits the bill:

- 100% biodegradable

- Naturally UV-resistant

- High tensile strength (approx. 29.98 g/denier)

Made from agricultural waste—no extra land or water use!

India, with its abundant banana cultivation, particularly in Tamil Nadu and Kerala, has a natural advantage, turning a low-cost waste into a high-value fabric. With this material being locally sourced, processed, and spun, India keeps costs down and quality up.

2. Import Market Opportunity: The Time is NOW!

Global fashion brands in Europe, the US, and Japan are pushing for sustainable supply chains. The EU’s Green Deal and upcoming textile labeling regulations make banana fiber a perfect fit.

Retailers and designers are actively seeking suppliers who can meet eco-certifications, traceability, and unique textures—all of which banana fiber offers.

Bonus: This is an early-stage trend, meaning low competition and high-margin potential for importers jumping in now!

3. In-Depth Product Comparison: Why India is Winning the Banana Fiber Race

Key Quality Factors

- Tensile strength: 29.98 g/denier – stronger than jute and nearly on par with hemp

- Moisture retention: 11-13% — optimal for breathability in apparel

- Fiber length: 0.5 to 1.5 meters – ideal for spinning into soft or coarse textiles

- Biodegradability rate: ~100% in 6 months

Optimal Technical Benchmark:

- A high-quality banana fiber textile should meet:

- Tensile strength above 25 g/denier

- Fiber purity above 85%

- Moisture content below 13%

India’s Output consistently delivers these figures thanks to indigenous retting and soft-extraction methods, especially in Tamil Nadu.

Competitor Snapshot:

- Philippines: Known for Abacá (banana hemp), but focused on paper and rope, not fashion textiles

- Indonesia: Emerging, but lacks scalability and consistency

- India: High-volume production, natural dye compatibility, and integrated handloom clusters

Varieties of Banana Fiber Products from India

- Woven Textiles (shirts, scarves, dress fabrics)

- Non-woven Mats & Bags

- Blended Yarns (banana-cotton, banana-silk)

- Home Decor (curtains, cushion covers)

Target Markets for Export

- Eco-fashion brands in Germany, Netherlands, France

- Sustainable packaging buyers in Japan & Korea

- Artisan & natural fabric retailers in the USA & Canada

Wrap-Up

Banana fiber is not just a trend — it’s a textile revolution in motion!

India’s supply edge, fiber quality, and sustainability scores make it the #1 choice for global importers looking to invest in fashion’s green future.

Start your Banana Fiber Textiles business and take them to international level today with expert support.

Chat with us directly on WhatsApp – [Click Here]

Discover more about us online – [Visit Now]

Learn More with BOAI – [CLICK HERE]

Tags: Import Banana Fiber Textiles from India to EU US and Japan Biodegradable UV Resistant and Ethically Sourced